In the manufacturing process of the battery, due to the process problems and the uneven material, so that the battery plate thickness, microporosity, the degree of activation of the active substance, there are small differences, such as the internal structure of the battery and the material is not completely consistent, will make the same batch of factory the same model of battery capacity, internal resistance and voltage parameter values can not be completely consistent.

When loading and using, due to the difference of temperature, ventilation conditions, self-discharge degree and electrolyte density of each battery in the battery pack, the inconsistency of battery voltage, internal resistance and capacity will be increased to a certain extent.

Battery life dilemma

Battery life after the group is much lower than the life of a single battery, the main reasons:

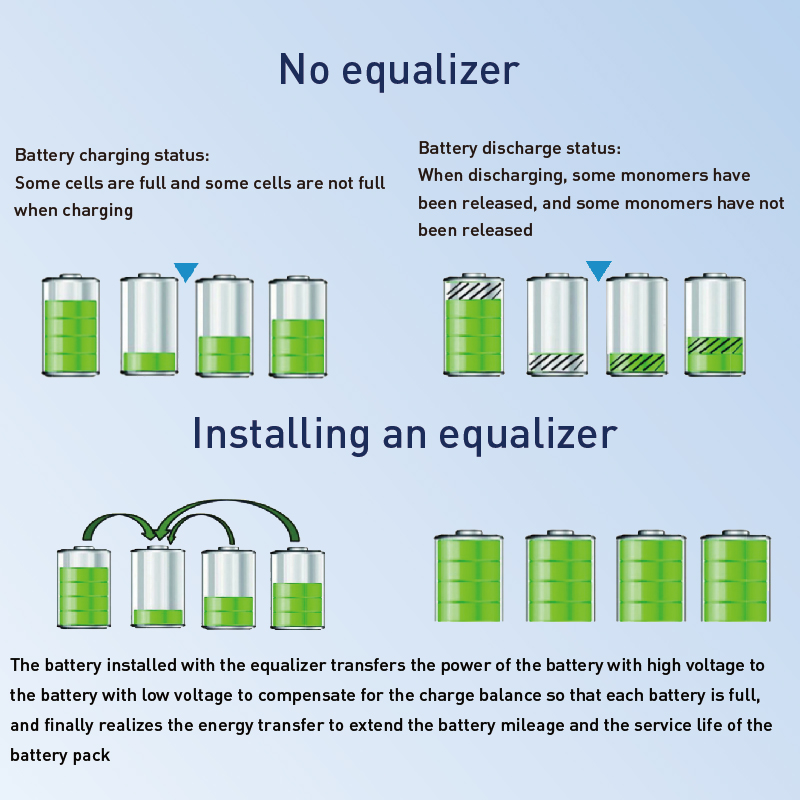

1. Due to individual differences between batteries, when charging, the battery with the smallest capacity is easy to overcharge, when discharging, the battery with the smallest capacity is easy to overdischarge, because the battery with the smallest capacity is damaged, the capacity becomes smaller, entering a vicious cycle.

2. The performance of a single battery directly affects the redischarge characteristics of the whole battery, and the capacity of the battery pack is reduced.

Therefore, it is necessary to balance the battery.

Balanced classification:

Passive equilibrium

Resistance energy dissipation type, in each single battery parallel a resistor shunt, energy dissipation balance is to consume the excess energy in the battery with a large capacity to achieve the balance of the entire battery voltage

Active equilibrium

The energy transfer mode transfers the high energy of a single to the low energy of a single, or supplements the entire group of energy to the lowest battery of a single, and requires an energy storage link in the implementation process, so that the energy can be redistributed through this link.

Battery equalizer, also known as battery balancer, is an electronic protection device that prevents the voltage imbalance between battery cells inside the battery from reducing the service life. When the voltage imbalance between battery cells, different battery cells charge and discharge speed is different, a battery cell is charged at the same time, other battery cells are in the state of overcharge or undercharge, and overcharge or undercharge will damage the battery, resulting in reduced battery capacity and shortened life. The battery equalizer can ensure the power balance between battery cells in real time, thereby extending the battery life by 5-30%.

Battery equalizer is an energy transfer equalizer that compensates the battery on both sides. When the voltage difference between the batteries connected in series exceeds 10 millivolts, the battery equalizer starts to work, and the current flows from the battery with higher voltage to the battery with lower voltage, and finally the battery reaches balance. It can be connected in a series connected battery for a long time to automatically maintain the balance of the battery without maintenance.

Battery equalizer is an active balancing system developed for many years, which solves the problem of charge and discharge balance of electric forklift, electric vehicle, electric tractor and other battery packs, effectively extending the battery range and battery life.