Lead-acid batteries are mostly composed of multiple independent battery cells connected in series. In the production process, due to the unavoidable production work difference, there are certain characteristic differences between the battery cells, which will cause the actual voltage of different battery cells to have certain differences.

Generally speaking, for a new battery, this difference in characteristics is negligible, but this difference will continue to be enlarged in the process e of the battery charging and discharging, and the amplification speed will continue to accelerate as the battery cell characteristic differences accumulate, eventually leading to The battery performance continues to weaken until it is scrapped.

This is why the forklift battery needs to be equalized charged once a month, but equalizing charging can only reduce the characteristic differences between battery cells to a certain extent, and cannot completely eliminate them. After all, some of the differences are completely irreversible.

There is a better solution for this shortened battery life due to the difference in battery cell voltage: battery equalizer.

It may be not cost-effective to equip a additional small equalizer for the lead-acid battery . After all, the value of a lead-acid battery is relatively lower than that of a lithium battery. If it is broken, just replace it with a new one.

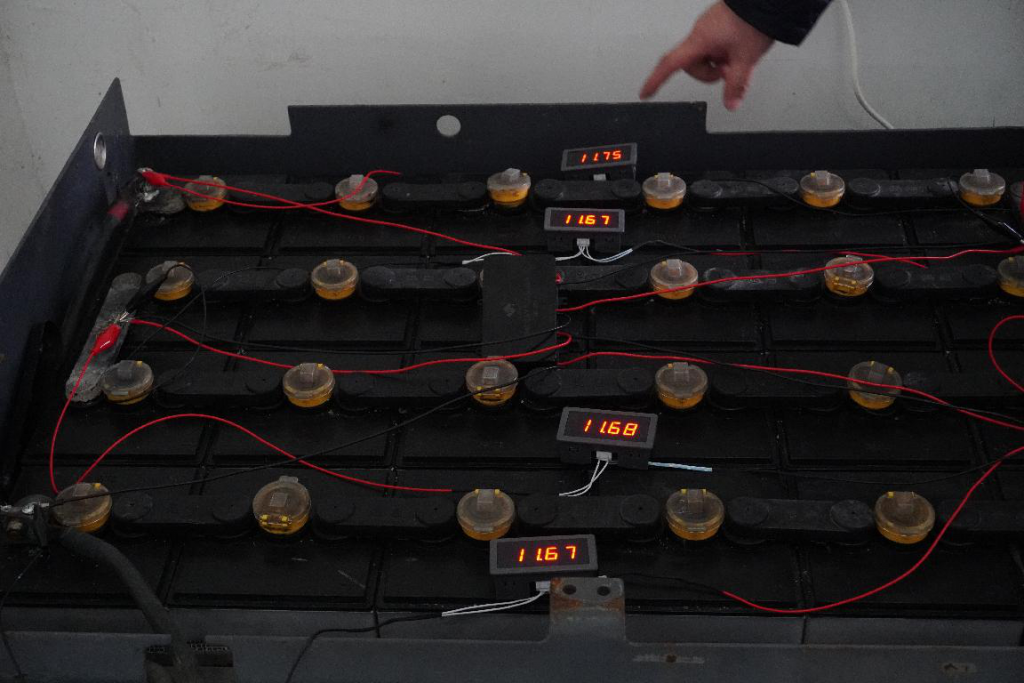

But for the lead-acid batteries with higher single value, such as electric forklift batteries, it is very necessary to equip an equalizer. After all, the price of changing a battery pack is enough to replace a small car. The price of a 48V400Ah forklift battery is generally more than 1.5W and can be used for 2-3 years. After using a battery equalizer, it can effectively extend the battery life to 4-5 years, which is equivalent to save 1W in two years.