Compared with fuel forklifts, electric forklifts have a significant cost advantage and are used more and more in logistics and production. Today, I will talk about the maintenance of electric forklift batteries.

The maintenance of the forklift battery is directly related to the final service life of the battery. The service life of the battery varies greatly. If the same battery is well maintained, a battery can be used for more than 5 years. If the maintenance is not in place, the same battery 1-2 It is not uncommon to be scrapped every year。

Forklift batteries are expensive consumables. The price of a 48V500ah forklift battery ranges from 1.6w to 2.7w. The difference in battery life caused by maintenance will be very obvious and directly reflected in the cost of electric forklifts.

1. Battery charge and discharge

(1) Make sure not to discharge the battery below 40% during use.

(2) Make sure the battery is in a well-ventilated environment when charging.

(3) When charging, a suitable charger should be used to charge the battery with an appropriate voltage to avoid charging the battery with an excessively high voltage.

(4) Cut off the power supply in time after charging is completed to avoid long-term floating of the battery.

(5)Equilibrium charge the battery every 500 working hours (3-4 months) to activate the plate inert oxide accumulated during use.

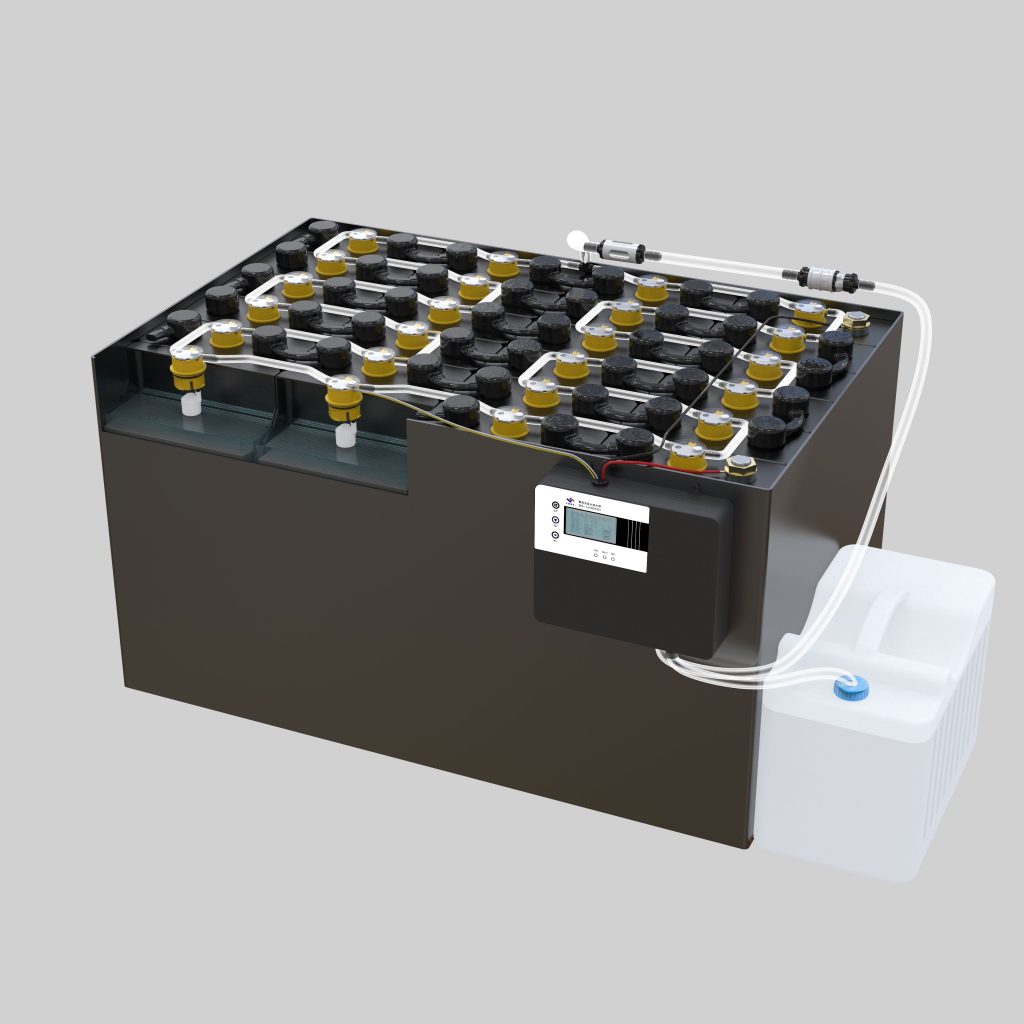

(What tool do you use to add water for electric forklift battery? Forklift battery water supply maybe your best choice.)

2. Daily maintenance of electric forklift battery

(1) Detect the battery surface, terminal posts, and battery connections: determine whether there is corrosive crystallization and whether the line connection is stable.

(2) Cleaning the battery surface: The accumulation of dirt will cause the battery surface to be short-circuited and energized, increase the battery’s self-consumption, and reduce the battery’s standby and use time. Here, pay attention to use a wet towel to clean the surface of the battery. Wiping with a dry towel can easily cause static electricity on the surface of the battery or even spark.

3. Battery water maintenance

The heat generated during battery use and charging will lead to the volatilization of water in the electrolyte, and the electrolysis reaction accompanying charging will also cause the water to be electrolyzed into hydrogen and oxygen to reduce. Therefore, it is necessary to regularly check the battery liquid level, and timely add water to the battery cells lacking water to supplement the lost water to ensure that the internal characteristics of the battery remain in a healthy state.

(1) Pay attention to the addition of distilled water or deionized water for maintenance. Water containing impurities may increase the electrolyte resistance after entering the battery, resulting in an increase in battery power consumption, an increase in heat release from the battery box, and a greatly reduced battery operating time. battery life.

(2) The amount of water to be added should be controlled at a height of about 2cm from the battery water inlet. Generally, most batteries on the market are equipped with a liquid injection valve with a liquid level indication function, and distilled water can be added according to the height indicated by the liquid injection valve.

(3) Pay attention to keep the liquid level of each battery cell as balanced as possible when adding water. Differences in electrolyte liquid level will lead to differences in battery characteristics, which will affect battery life in the long run.