一.Daily Inspection

- Liquid Level: Carry out a full inspection of the liquid level once a week (replenish distilled water or deionized water for about three days in a high-temperature environment). If the electrolyte level is too low, it will cause damage to the battery plates and separators and shorten the battery life. Observation method of the liquid level: first open the liquid filling cap, when it is lower than the bottom platform in the liquid filling cap, it means that the liquid level is too low and should be replenished in time; when it is parallel or slightly higher than the uppermost platform in the liquid filling cap, it is a suitable location.

- Terminals, wires, covers: Always check the junctions of the battery terminals and the connections to the wires for corrosion caused by oxidation, and check whether the covers are deformed and generate heat.

- Appearance: Dirty battery surface will cause leakage, so keep the battery surface clean and dry.

二.Maintenance

- Water replenishment: Add distilled water or deionized water according to the specified liquid level. Do not add too much distilled water in order to extend the water addition interval. Adding too much water will cause the specific gravity to drop and overflow the electrolyte, which will corrode the box and cables and affect the use of the battery. life or leakage.

- Charging: During the charging process, the battery will generate gas. The charging place should be well ventilated and there is no open flame around. At the same time, the oxygen and acid gas generated during the charging process will affect the surrounding area. Unplugging the charging plug during charging will generate an arc, so the charger should be turned off before unplugging. After charging, there is a lot of hydrogen remaining around the battery, no open flame is allowed, and the cover on the battery should be lifted for charging.

- Equalization charging: The battery pack should be equalized charging (ie, charging for a long time with a small current) once a month to maintain battery capacity and prolong battery service life.

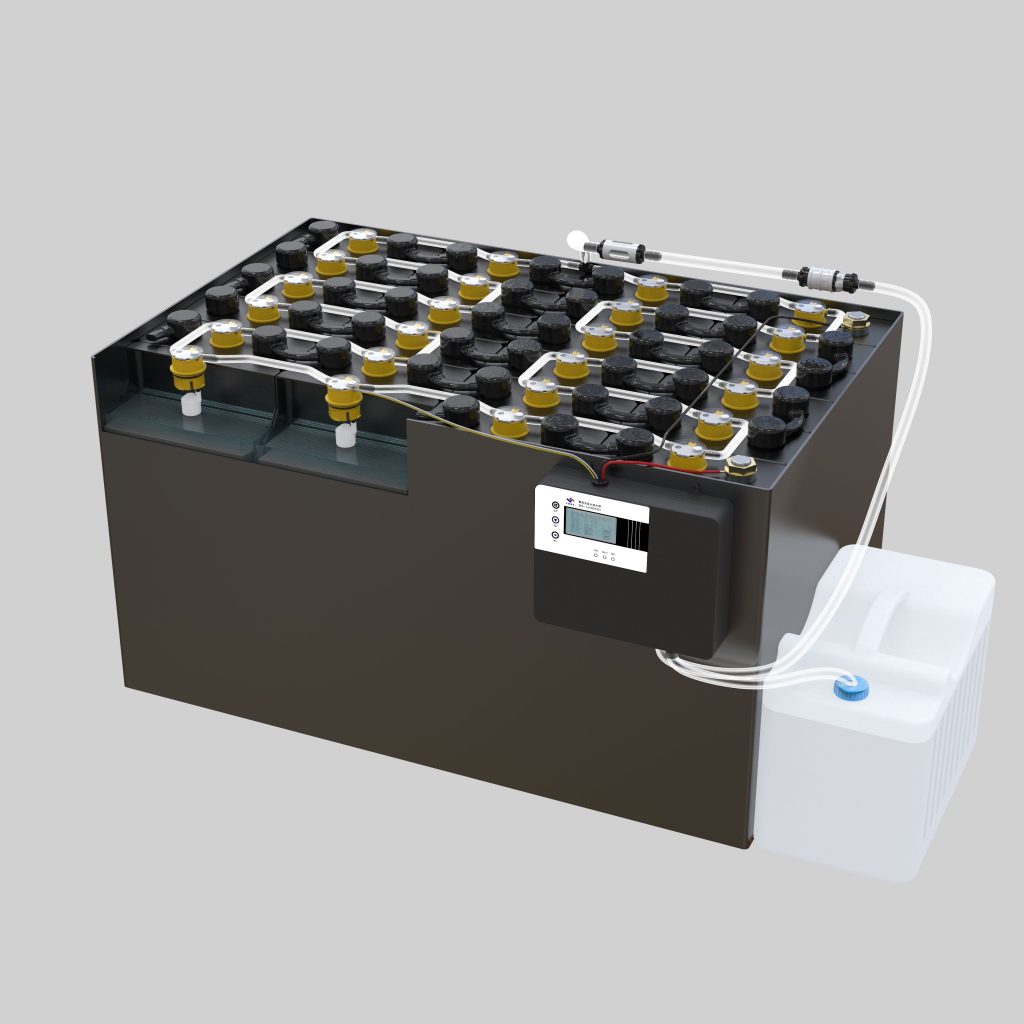

Forklift Water Injector System

三.Method of equalizing charging

First charge the battery normally, and after the charging is completed, press the balanced charging gear, and it is advisable to continuously charge the battery for 24-36 hours. During equalization charging, the voltage, density and temperature of each battery should be measured and recorded; before charging, the density and liquid level of the electrolyte should be adjusted to meet the requirements of the instruction manual.

Repair of terminal posts, wires (connection boards), and covers: it must be carried out by professional technicians designated by the manufacturer.

Cleaning: The surface of the battery should be kept clean. If there is dirt on the surface, it will cause a short circuit, and it will also cause corrosion of the pole and connecting strip. Please use a damp cloth when cleaning, otherwise static electricity will be generated. If there is no leakage hole at the bottom of the box, try to avoid rinsing with water to avoid excessive accumulation of water and corrode the box body.

四.Storage Place

- Storage place: Do not short-circuit it; a short-circuit caused by rain may cause fire and a small amount of hydrogen may be generated, so the battery must be stored in a ventilated and cool place.

- Discarded batteries: Discarded batteries still have electricity and should be stored in accordance with the storage method used.

五.Electrolyte

Check the specific gravity: use a suction hydrometer to check the specific gravity, do not spill the electrolyte during operation, and wear protective equipment.

Operations other than inspection: Professionals should be consulted, especially when replenishing electrolyte.

Electrolyte leakage: Because of the overturning or damage, which resulted in the electrolyte leaks , emergency treatment should be carried out immediately.

Forklift Water Fill Gun

-1024x731.jpg)

六.Operation of End-of-Life of Batteries

Operation of end-of-life of batteries: When the battery is nearing the end of its life, the electrolyte in the single-cell battery depletes very quickly, and distilled water should be replenished daily.

Disposal of discarded batteries: For used batteries, extract the electrolyte and disassemble the batteries. It can be negotiated whether to be recycled by the battery manufacturer.

七.Other consideration

The battery pack has high voltage and there is a danger of electric shock. Please wear insulating gloves during maintenance.

During use, the battery temperature cannot exceed 60°C.

The surface of the battery can store any maintenance tools or other metal objects, etc.

When it drops below 80% of the initial capacity, replace the battery with a new one based on the results of regular inspections.

Electrolyte spilled on skin or eyes: Rinse with plenty of water and seek medical attention.

Electrolyte spilled on clothes: Take off clothes immediately, rinse with water and then with weak alkaline soap.

Electrolyte leakage: When the electrolyte leaks to the outside, immediately neutralize it with lime, strong carbonated soda or carbonated soda, and rinse with plenty of water.