As we all know, water adding maintenance is a maintenance process written in the operation guide of electric forklift trucks, and the staff training will not miss the water adding training, which will occur in the use of battery: the battery will be short of water, and the battery will become hot, and it will become very hot in the charging process. Some batteries even expand. In this case, the battery is seriously losing water and is basically on the verge of being scrapped.

Let’s take a look at what factors which affected the water loss of lead-acid batteries

1. Water volatilizes

Water volatilizes naturally, which is affected by the working temperature of the environment, and also by the working intensity of the forklift. The battery will be hot at high strength, which leads to the constant change of the ambient temperature

2. Chemical Reaction

In the charging reaction, water is electrolyzed into hydrogen and oxygen. If the battery is overcharged, this reaction will be aggravated

3. Charger

If the charger matches the battery poorly, we don’t even know if the battery is overcharged

4. Electric quantity imbalance

If the battery characteristics are not balanced, there will be some overcharging, that is, some battery units will consume water a little faster

5, these are still good, most of the time lead-acid electric forklift is equipped with a spare battery, the workload increases, a few battery back and forth, you do not know the bottom of this recently added water, with you just finished adding water that battery is not run to others.

What do you say? Is it too big to think about? Some people say: let the forklift operator check the battery every day is not lack of water is not on the line?

In fact, in the face of the huge forklift battery pack, not only add water trouble, but also that it is very difficult to check one by one.

So how to judge whether the lead acid battery is short of water

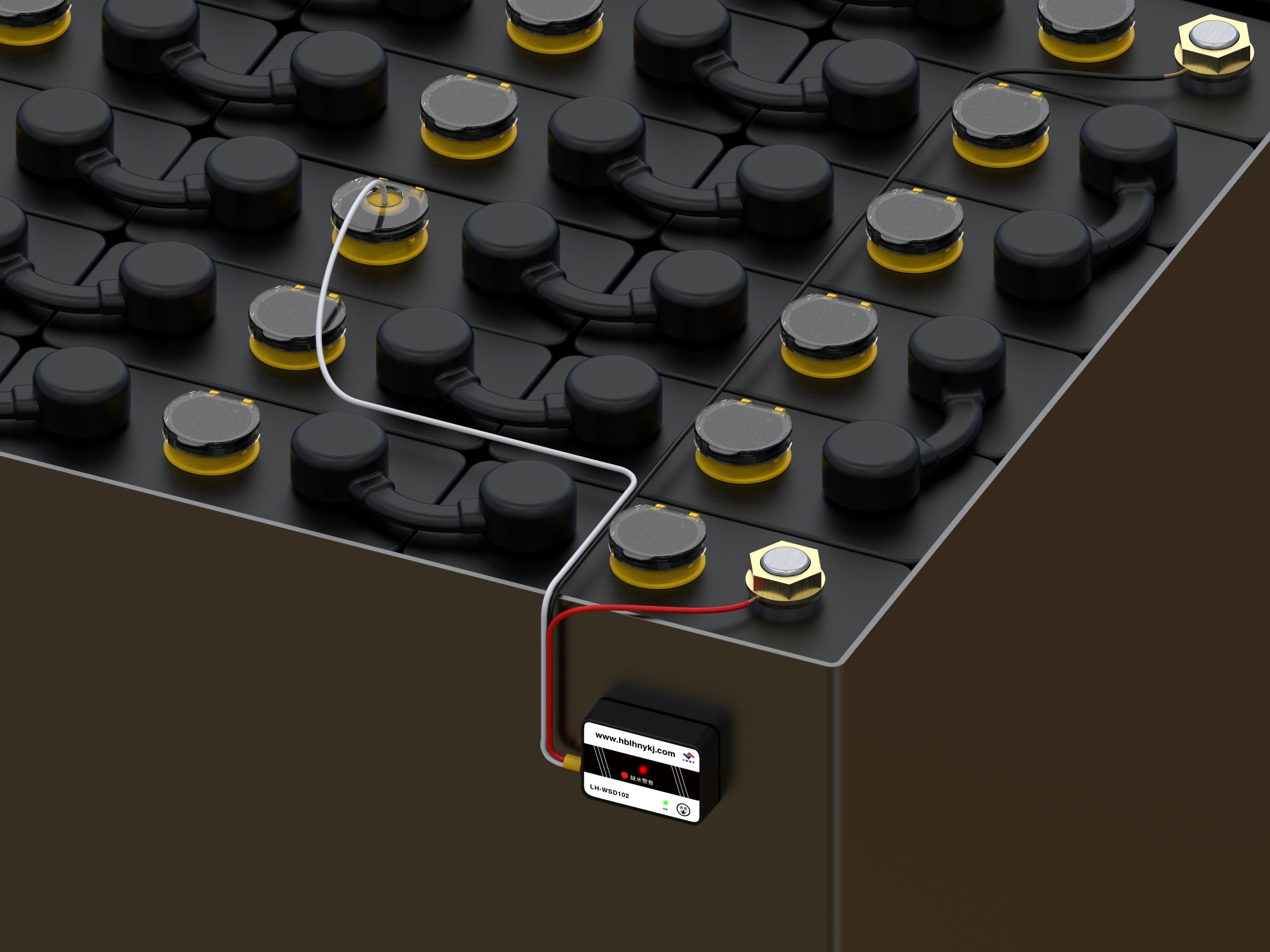

Of course, in the face of this situation, we are not helpless, just like this Lham battery liquid level indicator, is a professional forklift water alarm, as long as it is installed on the forklift, when the forklift lacks water, look at it, there is a buzzer remind, let the forklift thirsty call!

This product has a liquid rich lead-acid battery water shortage warning function, can help users timely informed of the battery water shortage information, remind users to timely battery water maintenance (only add distilled water or deionized water), to ensure the normal use of batteries, prolong the service life of batteries.

Working principle of battery level indicator

Equipment as equipment operation power supply is connected directly to battery cathode, electrolyte after induction rods, through the battery of electric signal under water, light is not bright, buzzer rang, when the electrolyte is lower than the induction rods, determine the battery under water, warning lights (red light flashing), buzzer warning (normal mode).

Conventional mode: water shortage warning light, buzzer warning function together

Silent mode: only water warning light function, use buzzer switch switch mode

The battery level indicator plays a key role in the water adding of electric forklift trucks. At present, the primary driving force of battery electric forklift trucks in all countries in the world comes from lead-acid batteries. This kind of open-mouth rechargeable batteries must be maintained and moisturized to continuously cause organic chemical electromagnetic energy, and water adding is an indispensable stage.

As a forklift truck accessories, battery forklift battery has account for higher purchasing cost, excellent maintenance regularly, is advantageous to the forklift battery battery service life of continuous, leong battery level indicator, is in the work, can help prompt forklift drivers and water, in the case of the lack of clean water, liquid level indicator is flashing lighting effects, Greatly solve the time to moisturize the “blind area”.