| Item No. | Head Diameter | Screw Diameter | Screw Pitch | Length | Condition | Test Project | Test Standard | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

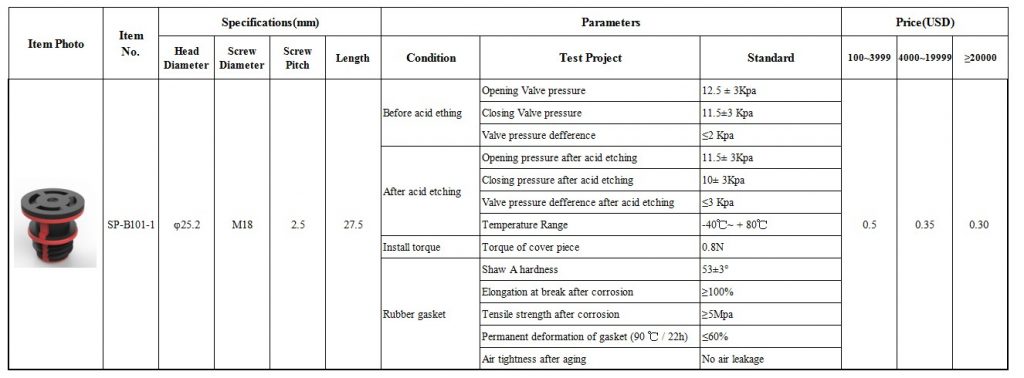

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Opening valve pressure | 12.5+/-2Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Closing valve pressure | 11.5 Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Valve pressure difference | ≤2Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Opening pressure after acid ething | 11+/-3Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Closing pressure after acid ething | 10+/-3Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Valve pressure difference after acid ething | ≤2Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Temperature Range | -40 ℃ – +80 ℃ | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Instal Torque | Torque of cover piece | 0.8N | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Shaw a hardness | 53+/-3 | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Elongation at break after corrosion | ≥100% | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Tensile strength after corrosion | ≥5Mpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Gasket is permanently deformed(90 ℃ /22h) | ≤60% | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Air tightness after aging | Not a flat |

| Item No. | Head Diameter | Screw Diameter | Screw Pitch | Length | Condition | Test Project | Test Standard | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

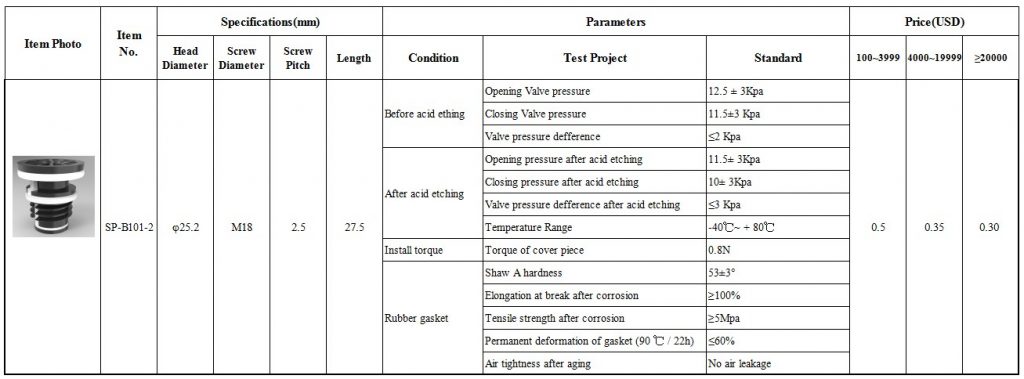

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Opening valve pressure | 12.5+/-2Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Closing valve pressure | 11.5 Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Valve pressure difference | ≤2Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Opening pressure after acid ething | 11+/-3Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Closing pressure after acid ething | 10+/-3Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Valve pressure difference after acid ething | ≤2Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Temperature Range | -40 ℃ – +80 ℃ | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Instal Torque | Torque of cover piece | 0.8N | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Shaw a hardness | 53+/-3 | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Elongation at break after corrosion | ≥100% | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Tensile strength after corrosion | ≥5Mpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Gasket is permanently deformed(90 ℃ /22h) | ≤60% | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Air tightness after aging | Not a flat |

| Item No. | Head Diameter | Screw Diameter | Screw Pitch | Length | Condition | Test Project | Test Standard | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

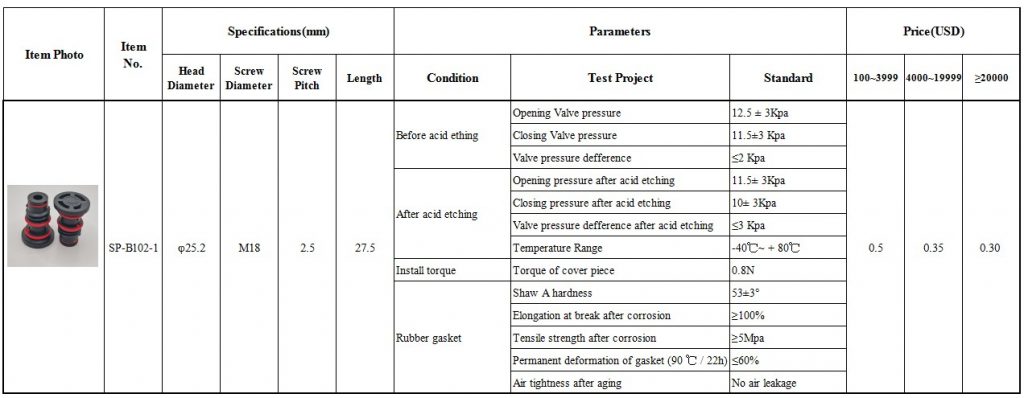

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Opening valve pressure | 12.5+/-2Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Closing valve pressure | 11.5 Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Valve pressure difference | ≤2Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Opening pressure after acid ething | 11+/-3Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Closing pressure after acid ething | 10+/-3Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Valve pressure difference after acid ething | ≤2Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Temperature Range | -40 ℃ – +80 ℃ | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Instal Torque | Torque of cover piece | 0.8N | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Shaw a hardness | 53+/-3 | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Elongation at break after corrosion | ≥100% | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Tensile strength after corrosion | ≥5Mpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Gasket is permanently deformed(90 ℃ /22h) | ≤60% | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Air tightness after aging | Not a flat |

| Item No. | Head Diameter | Screw Diameter | Screw Pitch | Length | Condition | Test Project | Test Standard | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

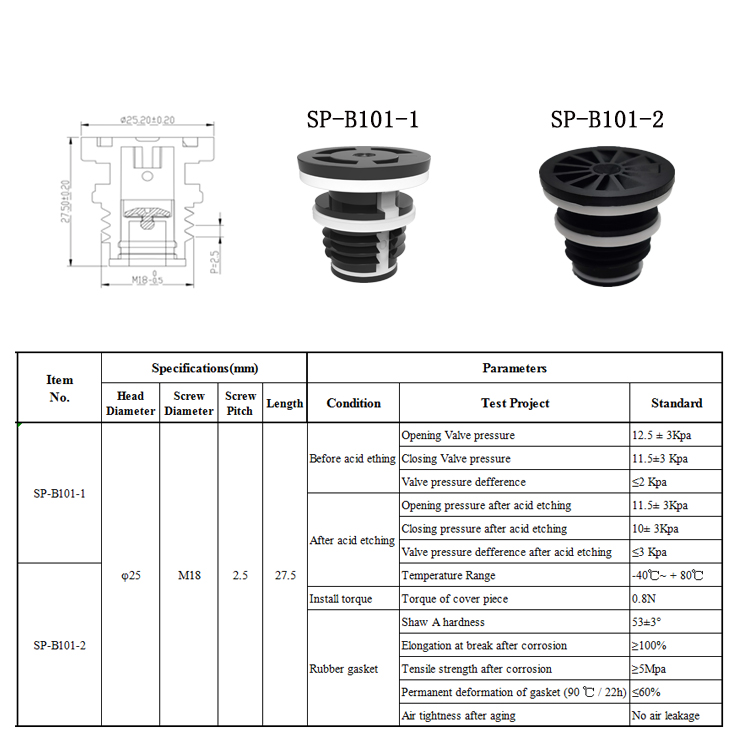

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Opening valve pressure | 12.5+/-2Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Closing valve pressure | 11.5 Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Valve pressure difference | ≤2Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Opening pressure after acid ething | 11+/-3Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Closing pressure after acid ething | 10+/-3Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Valve pressure difference after acid ething | ≤2Kpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Temperature Range | -40 ℃ – +80 ℃ | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Instal Torque | Torque of cover piece | 0.8N | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Shaw a hardness | 53+/-3 | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Elongation at break after corrosion | ≥100% | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Tensile strength after corrosion | ≥5Mpa | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Gasket is permanently deformed(90 ℃ /22h) | ≤60% | |||||

| SP-B101-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Air tightness after aging | Not a flat |

| Item No. | Head Diameter | Screw Diameter | Screw Pitch | Length | Condition | Test Project | Test Standard | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Opening valve pressure | 12.5+/-2Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Closing valve pressure | 11.5 Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Valve pressure difference | ≤2Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Opening pressure after acid ething | 11+/-3Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Closing pressure after acid ething | 10+/-3Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Valve pressure difference after acid ething | ≤2Kpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Temperature Range | -40 ℃ – +80 ℃ | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Instal Torque | Torque of cover piece | 0.8N | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Shaw a hardness | 53+/-3 | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Elongation at break after corrosion | ≥100% | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Tensile strength after corrosion | ≥5Mpa | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Gasket is permanently deformed(90 ℃ /22h) | ≤60% | |||||

| SP-B101-2 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Air tightness after aging | Not a flat |

| Item No. | Head Diameter | Screw Diameter | Screw Pitch | Length | Condition | Test Project | Test Standard | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Opening valve pressure | 12.5+/-2Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Closing valve pressure | 11.5 Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Before acid ething | Valve pressure difference | ≤2Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Opening pressure after acid ething | 11+/-3Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Closing pressure after acid ething | 10+/-3Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Valve pressure difference after acid ething | ≤2Kpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | After acid ething | Temperature Range | -40 ℃ – +80 ℃ | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Instal Torque | Torque of cover piece | 0.8N | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Shaw a hardness | 53+/-3 | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Elongation at break after corrosion | ≥100% | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Tensile strength after corrosion | ≥5Mpa | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Gasket is permanently deformed(90 ℃ /22h) | ≤60% | |||||

| SP-B102-1 | Φ25.2 | M18 | 2.5 | 27.5 | Rubber Gasket | Air tightness after aging | Not a flat |

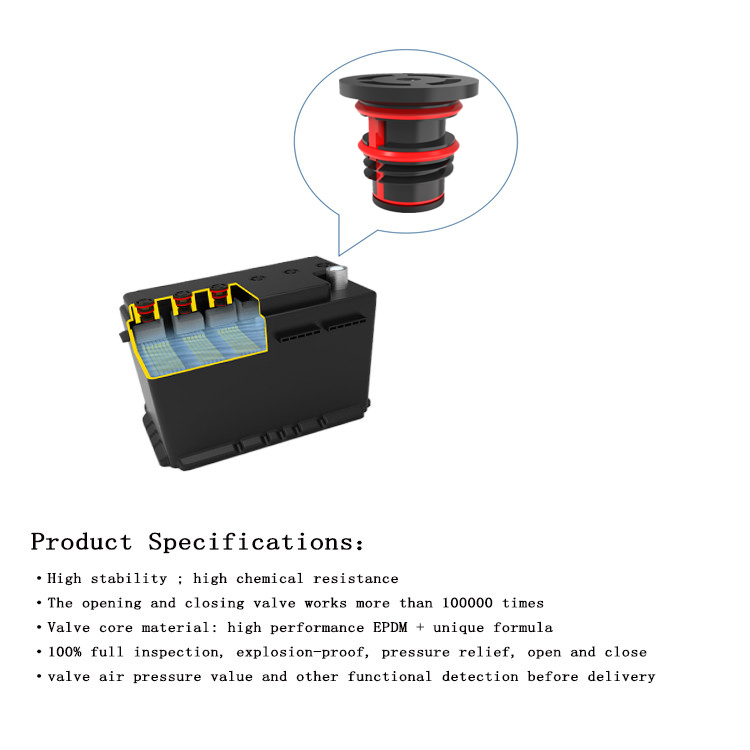

Product Specification:

1.High stability; high chemical resistance

2.The opening and closing valve works more than 1000000 times

3.Valve core material: high performance EPDM+unique formula

4.100% full inspection, explosion-proof,pressure relief,open and close

5.Valve air pressure value and other functional detection before deliver